-

You asked. We acted. | Since 1956

2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. Together, our 2,200 team members listen to customers and respond by developing and providing experience, unlike any other.

-

You asked. We acted. | Aircraft Sales

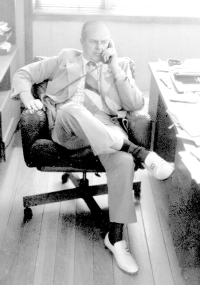

Iowa farmer and automobile salesman Donald Duncan learned how to fly in the 1950s. As he gained aircraft experience and developed deep friendships with aviators, he heard business operators asking to utilize aircraft as business tools. In 1956, he acted, buying into the Beechcraft dealership that would become Duncan Aviation. 60 years later, we still provide aircraft sales.

-

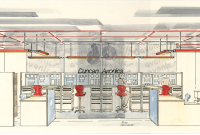

You asked. We acted. | Lincoln, Nebraska

Donald Duncan’s customers expressed the desire to have an executive lounge and meeting spaces available at a centrally located fuel stop. In 1963, the city of Lincoln, Nebraska, was developing a new Municipal Airport for general aviation. Donald acted and built a first-class facility with a warm reception area, a plush executive lounge, a flight planning room and catering services. In addition, the facility boasted hangar space for complete, certified aircraft maintenance and repair.

-

You asked. We acted. | Fuel Services

Since 1963, Duncan Aviation has provided the best in FBO amenities for customers and visitors alike. Our line crew is known for quick and convenient line service and our front desk personnel are known for hospitality.

-

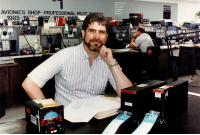

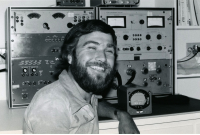

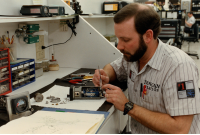

You asked. We acted. | Avionics & Instruments

Business aircraft operators have always wanted the best in safety and efficiency. As new cockpit and system technology emerged in the 1960s, those who had purchased Bonanzas, King Airs, Barons and even Learjets without it were interested in having their aircraft upgraded. Donald Duncan listened to their wishes. In 1966, he acted by hiring Don Fiedler, an electronics engineer, as the company’s 17th employee. His job was to install and repair avionics equipment for a variety of business aircraft. Decades later, Duncan Aviation is still providing operators with the best in avionics and instrument repair and avionics upgrades.

-

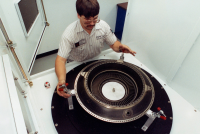

You asked. We acted. | Accessories

In the late 1960s, Duncan Aviation became a factory authorized Learjet Service Center. As sales and maintenance relationships with Learjet operators deepened, customers began to ask then-president Robert Duncan for one-stop capabilities. In 1978, he acted and the company started its accessory shop to repair Learjet accessory units. In 1980, Duncan Aviation overhauled its first Learjet landing gear. Decades later, Duncan Aviation is still providing operators of all the main business aircraft models with the best in accessory inspection, repair and overhaul.

-

You asked. We acted. | Paint

By the late 1970s, Duncan Aviation had hundreds of loyal customers who had purchased their aircraft from the company and liked having it maintained at the facility. They began to ask for even more capabilities, especially exterior paint and interior refurbishment. In 1979, Duncan Aviation acted, opening a new paint hangar.

-

You asked. We acted. | Engine

By the late 1970s, Duncan Aviation had hundreds of loyal customers who had purchased their aircraft from the company and liked having it maintained at the facility. They began to ask for even more capabilities, including engine maintenance and inspections. In 1981, Duncan Aviation acted, working with engine OEMs to obtain authorizations for TPE331 and then TFE731 engines.

-

You asked. We acted. | Interior

By the late 1970s, Duncan Aviation had hundreds of loyal customers who had purchased their aircraft from the company and liked having it maintained at the facility. They began to ask for even more capabilities, especially exterior paint and interior refurbishment. In 1981, Duncan Aviation acted, the company began providing comprehensive interior completions.

-

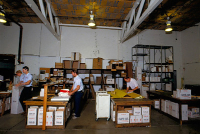

You asked. We acted. | Parts Consignment

In the mid-1980s, new surplus aircraft parts were abundant throughout the industry. As business flight missions changed, operators would switch aircraft, leaving spare parts for their former aircraft taking up valuable storage space. Then Duncan Aviation president Robert Duncan heard operators comment about this waste of money and resources. In 1984, he acted and formed the Aviation Parts and Communications division (AVPAC), which gave operators a way to consolidate their inventories and consign those parts worldwide.

More than 30 years later, Duncan Aviation still provides operators with parts and rotables services that include consignment, parts location and 24/7/365 AOG services.

-

You asked. We acted. | Avionics Satellites

By the early 1980s, Duncan Aviation had an excellent reputation for responsive service and technical knowledge. Much of that reputation came from development of the company’s large avionics loaner pool and free telephone troubleshooting assistance. One comment then Duncan Aviation president Robert Duncan always fielded was whether a Duncan Aviation shop would come to a customer’s home airport. In 1985, Duncan Aviation acted. The company worked with maintenance facilities around the country to develop agreements that allowed mutual customers to receive local avionics service from Duncan Aviation technicians.

More than 30 years later, these seedling shops have grown into the current network of 25 avionics repair shops and additional fixed locations that Duncan Aviation operates at busy corporate airports around the country.

-

You asked. We acted. | Aircraft Acquisition

In the early 1990s, Duncan Aviation team members had completed more than 3,000 aircraft sales transactions and had loyal customers who purchased inventory and consigned aircraft from the aircraft sales team. But occasionally, someone would call asking for help deciding which make and model aircraft they needed for their particular business needs. That was consultative service that didn’t really exist at the time until, in 1992, Duncan Aviation acted and started JetResources, the industry’s first aircraft acquisition service that guided purchasers from selection and comparison through negotiation and the final pre-purchase evaluation.

-

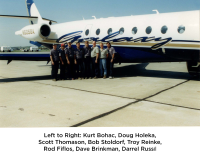

You asked. We acted. | Battle Creek, Michigan

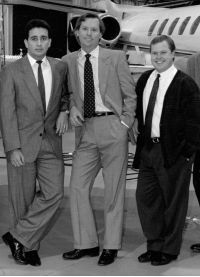

By the late 1990s, Duncan Aviation consisted of a main service facility in Lincoln, Nebraska, and more than a dozen satellite avionics facilities across the United States. The hangars in Lincoln were busy and customers were asking then Duncan Aviation President Aaron Hilkemann and Chairman Robert Duncan for additional locations to receive tip-to-tail aircraft services.

In 1998, they acted. The perfect match came along when the Kal-Aero facilities in Battle Creek and Kalamazoo, Michigan, became available. Kal-Aero was a major player in the Great Lakes region with a great reputation. The merger provided Duncan Aviation customers with high-quality service work performed under the Duncan Aviation umbrella.

-

You asked. We acted. | Engine RRT

By the turn of the century, Duncan Aviation had thousands of loyal customers calling Duncan Aviation technicians when they were AOG with engine and avionics issues. Duncan Aviation engine road crews were kept busy, and customers kept asking for them to respond even faster when they were stranded.

In late 2000, Duncan Aviation responded with the first-ever mobile engine service team located at a launch office that was away from a main service facility. This dedicated, ready-to-travel service team was located in Dallas near a large commercial airport hub with the sole purpose of providing stranded customers with rapid engine service in the field.

Duncan Aviation provides operators with Rapid Response engine services from an expanded network of launch offices.

-

You asked. We acted. | Provo, Utah

By the mid-2000s, customers were asking for facilities closer to them, especially in the western United States. In 2008, Duncan Aviation acted by selecting Provo, Utah, as an expansion site. In 2010, the hangar doors opened and Duncan Aviation began providing maintenance, engine and avionics services to aircraft operators from the Utah location. Since then, capabilities in Provo have slowly grown to include light interior work as well.

-

You asked. We acted. | 2017 and Beyond