At Duncan Aviation, we have recently troubleshot several Hawker aircraft that were experiencing stiff airbrake operation or, on a small handful, an airbrake handle that crept toward the open position after the initial opening of the airbrakes.

As you investigate this issue, make sure you verify that the airbrake jack selector valves themselves are not the cause. Improper cable tensions and rough and/or seized pulleys/cable connection points are also a possible source for this discrepancy.

A Mandatory Service Bulletin (27-3589) was issued back in March 2004 regarding corrosion in the airbrake selector valves. This applied to airbrake jacks manufactured from 1993-2002 or jacks with valve body/plunger replacement during the same period. These jacks are overhauled at 3000 hour intervals, so most, if not all, jacks in service are compliant.

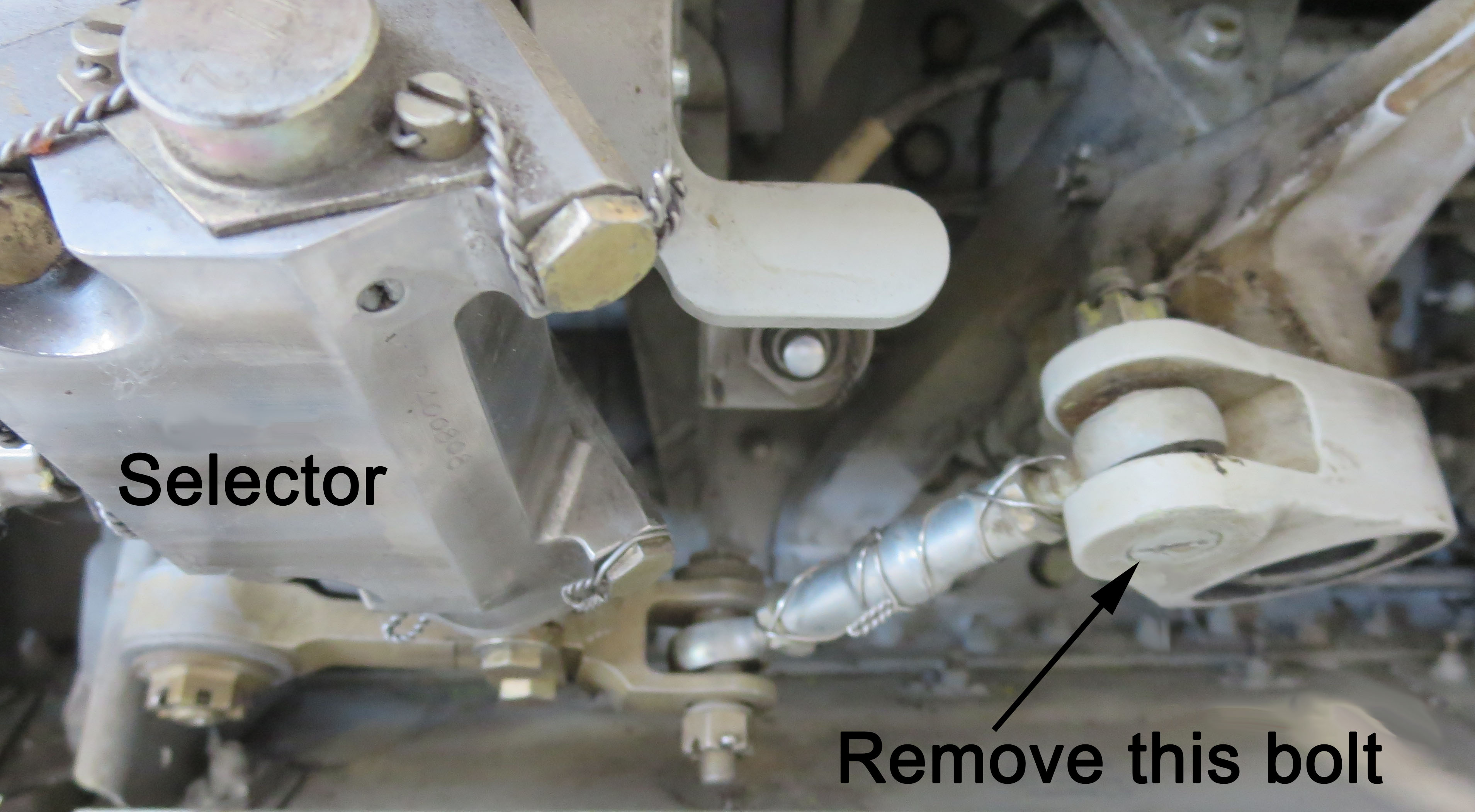

It is an easy procedure to confirm whether the selector valve is the culprit. Simply remove the jack link bolt from the wing bellcrank and check for stiffness when the selector valve lever is displaced either direction, it should return to a neutral position.

Caution, the airbrake will move if hydraulic pressure is present. All parts of the airbrake system must have freedom of movement and be rigged properly for continued trouble-free operation.

December 2025

December 2025

October 2025

September 2025

August 2025