Hot weather is coming up. Having your Falcon 900 series aircraft cooling system at top performance is not just a convenience but can save you money in the future.

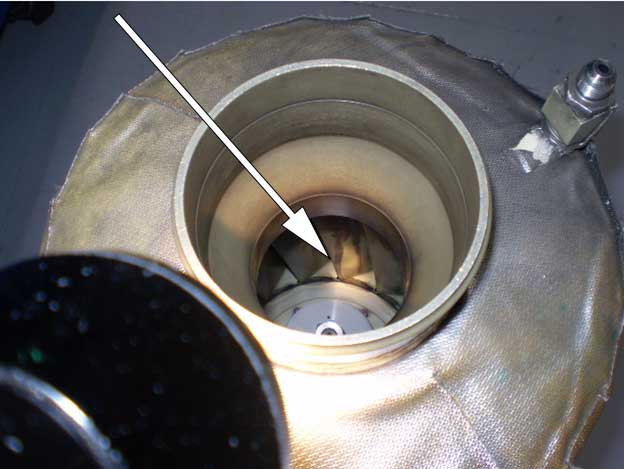

During the course of your next 12-mos inspection, pay particular attention to the swirl vanes inside the LP water separator can assembly (PN B31WA3023). Task card 21-52-19-200-801-01 para. 5.D calls for the technician to remove the LP coaleser water sock and perform a measurement of the relief valve support to check for collapsing of the swirl vanes.

If this measurement fails, the usual cause is ice build-up inside the separator can, which is indicative of a failure of the turbo-cooler anti-ice system. Troubleshooting the anti-ice valve, amplifier, and downstream temperature probe is imperative before replacing the LP separator assembly.

Dassault has published Falcon Service Advisory FSA 21-50-014-R04-A, which talks about this scenario and is still relevant to this day.

Check for bent or damaged swirl vanes.

January 2026

December 2025

December 2025

October 2025

September 2025