Do you understand the importance of identifying and repairing even minor damage on your Goodrich® pneumatic de-icers? Unrepaired surface damage can lead to ingress of water into your de-icing system, ultimately creating further costly damage to internal components such as valves and sensors. Additionally, unrepaired damage limits proper function of the de-icer itself decreasing effective ice shed.

Understanding Repair Limitations

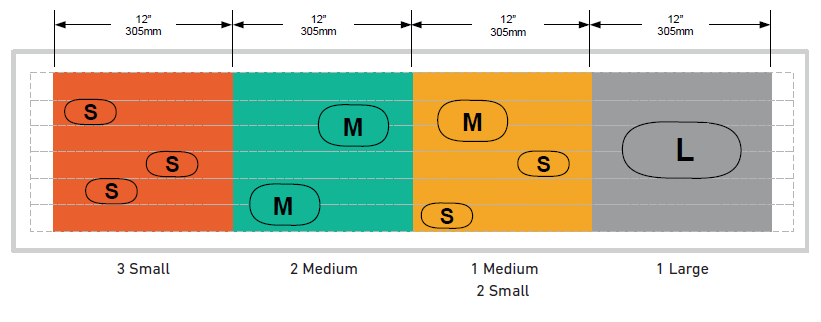

Certain types of damage cannot be repaired and require replacement of the de-icer. These include cuts, tears or ruptures that extend through the bondside fabric layer, broken stitch or thread, and damaged areas which exceed 4”x9”. Otherwise, the allowable number of repairs is as follows:

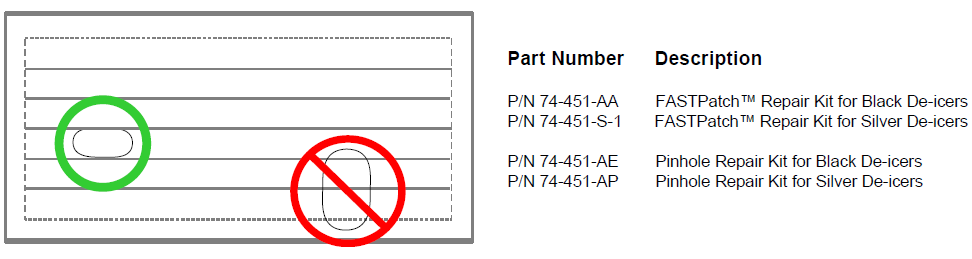

Authorized Repair Kits

Goodrich offers patch and pinhole repair kits for black and silver de-icers. Each of the kits include all the materials needed to complete repair. It is important to note that, like the de-icer, patches have a one-way stretch the width of the patch to allow for optimal inflation and ice shed. The patch must be installed with the length parallel to the de-icer tubes as shown in the image below. Failure to do so may result in the patch lifting when de-icers are inflated. Similarly, the pinhole repair material is also designed to stretch with inflation.

For sales inquiries and assistance on figuring out what kit you need, contact, Duncan Aviation Parts & Rotables Sales at 800.562.6377.

February 2026

February 2026

February 2026

February 2026

February 2026