Engine Condition Trend Monitoring, or ECTM, is defined as using engine operational data to find symptoms of damage, deterioration, or excessive wear. Essentially, it’s a technique that continuously monitors the health of your aircraft engines.

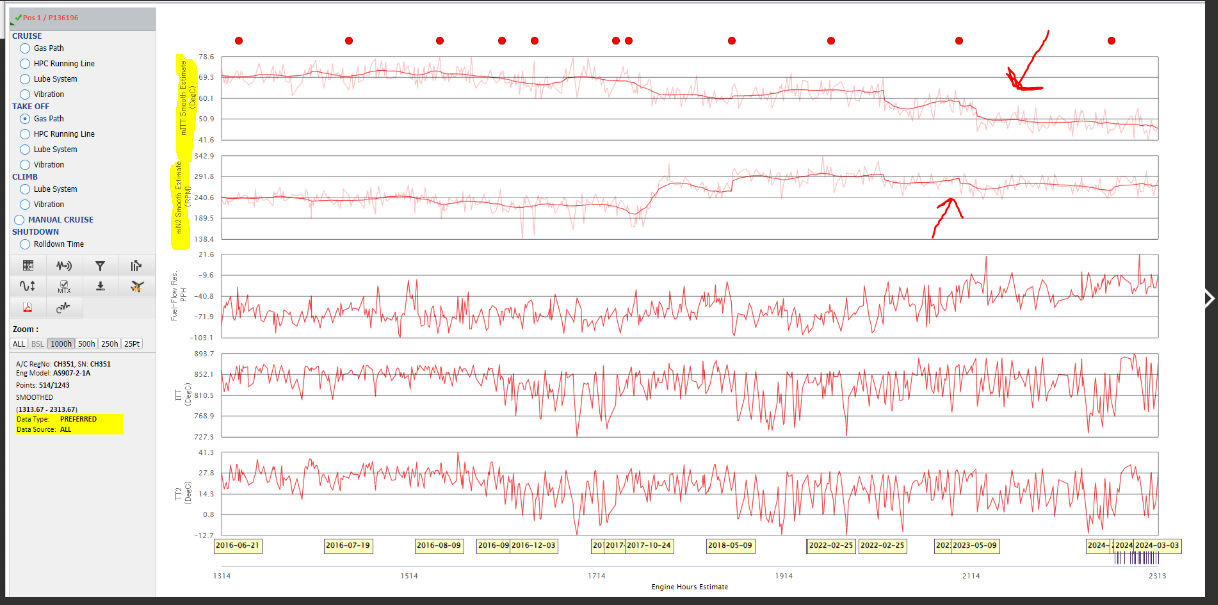

By tracking a known set of parameters, usually altitude, OAT, airspeed, ITT, N1/N2 RPMs, fuel flow, and vibrations, operators are more able to predict needed maintenance before a failure occurs. Knowing these parameters will not stop the initial problem from happening, but it is a great tool to predict a failure before secondary damage occurs. An example of what information you may receive are downward trends of performance and changes in RPM that could lead to early Hot Section deterioration or point to engine or aircraft bleed leaks. The trend may even show something as simple as it’s time to do an engine water wash.

Many companies provide this subscription-based trending analysis service. Properly trained, anyone can manually do the analysis but keep in mind that the risk for error is high. These companies all use computers and software to interpret the data, and as a part of the service provided, will notify the operator of any anomalies that need addressing. Some might say that the flight crews could notice these trends and that may be true for significant or sudden changes to performance. ECTM will identify subtle changes over a period of time that a flight crew won’t notice.

Every flight, the aircraft is in different environmental conditions that may not give a clear picture of performance to the flight crews. The ECTM software will calculate the information you provide and correct it for standard day conditions, information that is easily compared from flight to flight and then makes a comparison to a model, specific to each engine model.

Performing ECTM will always be a recommendation whether the engines/aircraft is old or new. An effective ECTM program consists of four parts: capturing In-Flight data, converting and comparing data to mathematical models, detecting anomalies from the trend analysis, and notification of when anomalies exist.

Knee Board trending is one means of gathering and submitting the necessary information to your ECTM provider for the older aircraft operators. Knee Board refers to the flight crew writing the required information down at a specific time during each flight. Newer aircraft are capable of digitally recording this information onto a storage device mounted on the engine or in the aircraft. A laptop computer is then used to download this information to a file format that can be emailed to your ECTM provider.

Modern engines are utilizing the On-Condition programs more and more, where a teardown inspection of the engine for a Hot Section or even an overhaul is not performed. To participate in these programs, you’ll find that ECTM is required. Although it will always be advisable to perform ECTM, it is recommended to start trending within the first 100 hours since new, just after a hot section inspection or overhaul. Some operators have started just before the engine going in for overhaul and that’s fine. The point is to enroll and begin doing the trending. In the end, the cost of maintenance and the cost of each flight hour will be reduced.

For questions about ECTM, reach out to me or any Duncan Aviation Engine Service Sales Rep.

Shawn Schmitz

Engine Tech Rep Program Manager

Challenger, Citation, Embraer, Gulfstream Lincoln, NE (LNK)

+1 402.479.8166

Shawn Schmitz

Engine Tech Rep Program Manager

Challenger, Citation, Embraer, Gulfstream Lincoln, NE (LNK)

+1 402.479.8166

February 2026

February 2026

February 2026

February 2026

February 2026