“I understand why customers like this engine. It is very reliable and has a good reputation in the fleet,” says Shawn Schmitz, the HTF Program Manager at Duncan Aviation.

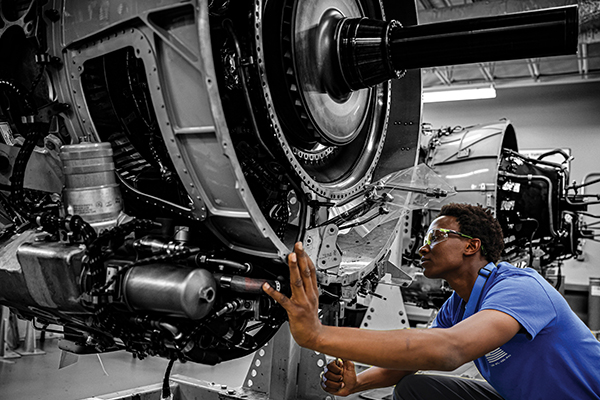

The Honeywell HTF7000 Series engine is renowned for its reliability and high performance, playing a crucial role in business aviation. At Duncan Aviation, a long-time partner with Honeywell and an HTF Series Authorized facility, we continue to expand our engine maintenance capabilities, reflecting the growing demand for these engines and our commitment to exceptional customer service.

If you fly one of the many popular business aircraft, such as the CL300, CL350, CL3500, G280, Embraer Legacy 450, or Legacy 500, Praetor 500 and 600, and Citation Longitude, finding quality, available, and responsive HTF7000 Series engine maintenance service is vital for operations.

Since receiving authorization for repairs on the HTF7000 series in 2015, we have not only expanded our in-house service capabilities, but our engine maintenance shop, which initially shared a 4,000-square-foot space in a hangar backshop, now occupies a modern, state-of-the-art, 20,000-square- foot facility in Lincoln, Nebraska. This expansion includes a dedicated on-site NDT (nondestructive testing) lab, a flow and balance room, a large engine clean room, and a state-of-the-art paint booth, among other enhancements. This ensures all aspects of the HTF7000 maintenance process are handled efficiently and effectively in one location controlling downtime, quality, and added expenses.

The growth of our HTF program has been largely driven by word of mouth, a testament to the quality of service provided. “We are not the largest HTF service provider,” says Shawn. “But our customers appreciate our focus on quality over quantity and our dedication to ensuring they are satisfied.”

This satisfaction is reflected in our access to new customers. Over the past decade, the company has experienced an average annual increase of 22% in the number of customers seeking HTF engine services.

“As the fleet continues to grow, we are positioned to meet this demand with quality team growth,” says Shawn.

Duncan Aviation keeps customers flying with a pool of rental engines and other industry resources. By letting us do all the legwork, such as working with MSP, lining up rental engines, handling billings, and shipping parts, operators can experience hands-free maintenance.

Communication is key for clients. Even if they wish to be hands-off, they need to be kept informed of any issues and how they are being addressed. At Duncan Aviation, we treat engine maintenance as a team effort. Everyone who works on the engines is well- trained and capable and can talk a customer through what is happening and what they can expect.

This August, Duncan Aviation broke ground on a significant expansion of our turbine engine overhaul facility at the Lincoln Airport in Lincoln, Nebraska.

This new 36,000-square-foot Pratt & Whitney Designated Overhaul Facility will conduct hot sections and overhauls on PW300 and PW500 turbofan engines. Atec, Inc., based in Houston, Texas, is contracted to engineer and construct a 20,000 lb. Thrust Class engine test cell and control room. Hot section inspection services will be operational by the end of 2024, with full overhaul capabilities coming online in early 2026.

With the demand for the HTF7000 engine service expected to increase in the near future, we are preparing to expand our team and enhance training programs. Shawn emphasizes the importance of education, ensuring that all team members are well- versed in the latest Service Bulletins and repairs. This knowledge allows the sales team to better support customers and ensures consistent service quality across all Duncan Aviation locations, including Battle Creek, Michigan; Lincoln, Nebraska; Provo, Utah; and throughout our Rapid Response Team network.

Looking ahead, Duncan Aviation is poised to further enhance our capabilities by adding in- house HP case shroud grinding by the end of 2025.

This will include a significant investment in the inventory of rotable HP cases, enabling the creation of match set assemblies.

Our ongoing investment in the HTF7000 program, coupled with our commitment to customer service and technical excellence, ensures that we remain a leader in the business aviation maintenance industry. As the number of HTF7000 engines in operation continues to grow, customers can count on us for reliable, efficient, and comprehensive engine maintenance services.

With one call, we can be at your location with the proper tooling to perform engine R&Rs, the 4,800/9,600- hour (Praeter: 4,500/9,000-hour) borescope inspections, periodic maintenance, hot-end entry, aft sump bimodal repair, Service Bulletin incorporation, and troubleshooting.

For 24/7 AOG support, visit: www.DuncanAviation.aero/services/aog