Most aircraft use some type of hydraulics in their configuration. Whether it be actuation, braking or shock absorption, these systems rely on the internal seals' integrity to function correctly. The seals keep the fluid contained in the proper working area to ensure correct operation and prevent leakage. In many cases there are external moving parts that come into contact with these seals, such as actuator pistons and shock strut tubes.

For the seals to operate effectively these externally moving parts must remain clean, lubricated, free of contamination and damage. Many aircraft require inspection, cleaning and lubrication at certain intervals. It is important that the externally moving parts, which are usually chrome-plated, should be lubricated with the same fluid used in the system or specified by the aircraft maintenance manual.

For the seals to operate effectively these externally moving parts must remain clean, lubricated, free of contamination and damage. Many aircraft require inspection, cleaning and lubrication at certain intervals. It is important that the externally moving parts, which are usually chrome-plated, should be lubricated with the same fluid used in the system or specified by the aircraft maintenance manual.

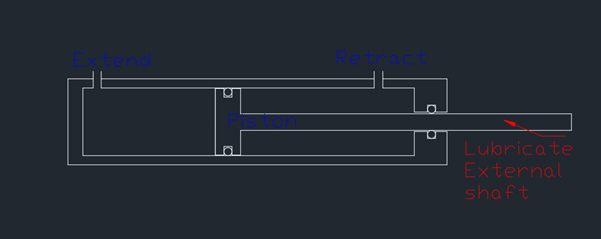

The chrome portion of these hydraulic devices needs a thin film of lubricant to prevent damage to the seals they come in contact with. Most seals are designed to allow a slight amount of leakage as a self-lubricating feature. However, many failed seals on these types of components can be traced back to installation and initial actuation on a non-lubricated surface. The maintenance manual may not always require initial lubrication but components coming from inventory or from repair shops may not be properly lubricated due to length of time sitting on the shelf or from packaging/handling. It is recommended that the lubrication procedure be followed before operation of freshly installed components and never actuate a hydraulic unit that is not properly lubricated.

The landing gear components are open to the elements and more subject to debris and contamination. We recommend wiping down the chrome portion of the landing gear struts and actuators before each flight if possible.

Five Consequences of Ignoring Landing Gear Trunnion Corrosion

Failures On The Embraer Phenom and Praetor Emergency Light Power Supplies

Essential First Steps To Proper TR Rigging On CL-600 Series Aircraft To Save Time And Avoid Damage

How Much Wear Do I Have Left On My Aircraft’s Brakes?

Comparing Aircraft Maintenance Quotes: Avoiding Sticker Shock