With icing season approaching, it is important to complete de-icing system functional checks to ensure that your pneumatic and electrothermal de-icing systems are working properly. When performing visual inspections of the pneumatic boots, you may find the following types of common damage that reduce optimal performance of your de-icing system.

|

Cold-Cracking Cold-cracking occasionally occurs when the de-icers are cold-soaked below their designed operating parameters (-40 °F/-40 °C) and inflated when brittle. Long slits or cracks on the de-icer that appear relatively straight and are usually in the middle of the air tubes may be cold-cracking. |

|

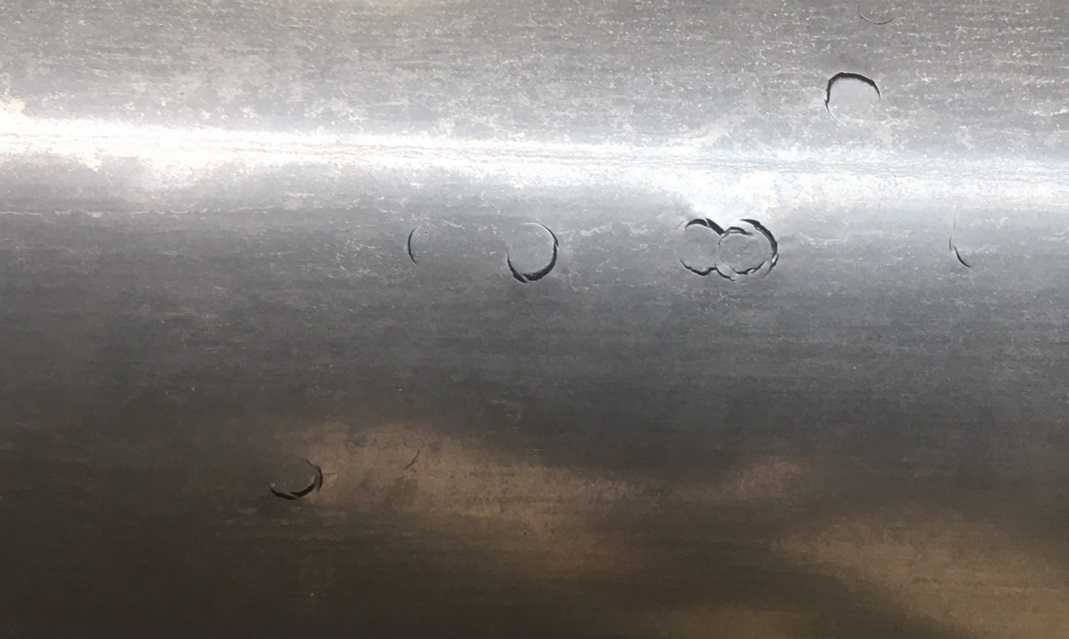

Cold Impact Damage Similar to cold-cracking, cold impact damage may also occur when de-icers are cold-soaked below -40 °F/-40 °C. These small dents or cracks, which are often in a curved or half-moon shape, are caused when environmental foreign objects, such as ice crystals or hail, are encountered in flight. Neither cold impact damage nor cold-cracking are warrantable defects, and while they may be repaired if within the repair limits, the damage often extends beyond approved repairs. |

|

Broken Stitchline Broken stitchlines can occur due to foreign object damage either in flight or on ground. It is important to inspect for this failure as even a single broken stitch requires de-icer replacement to prevent further breakage caused by inflation cycles. |

For more information on these and other types of common pneumatic de-icer damage, click on the icon below to refer to Collins Aerospace, Goodrich SNL 05-064. This document provides examples as well as details regarding repairability and warranty.

January 2026

January 2026

January 2026

January 2026

December 2025