In the calibration world, there is a distinct difference between a calibration and an adjustment. Often these two words are used interchangeably, which can lead to confusion.

In the calibration world, there is a distinct difference between a calibration and an adjustment. Often these two words are used interchangeably, which can lead to confusion.

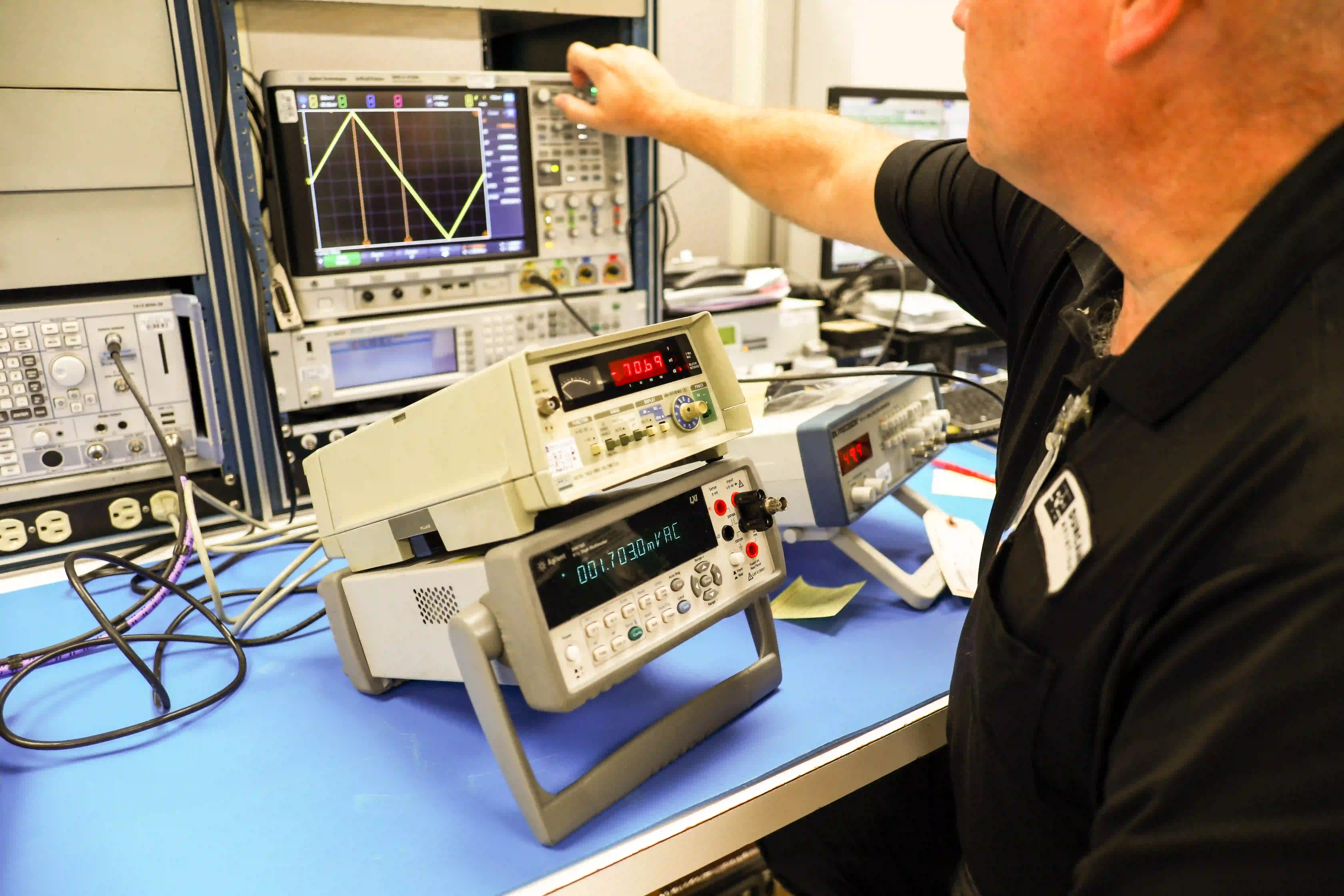

Simply put, calibration is the act of comparing an item with an unknown value against a reference standard with a known value to make a quantitative evaluation.

An adjustment, on the other hand, makes a change to the item. The goal of this adjustment is to bring the item within a specified range or tolerance as compared to the reference standard so that it will pass calibration.

A calibration may or may not necessitate an adjustment, whereas an adjustment should always be followed by a calibration to ensure the item is functioning properly.

Call us if you have any questions about calibrations or want to discuss a plan for getting your tools on a calibration schedule.

December 2025

August 2025

July 2025

November 2024

September 2024