Many aircraft these days are equipped with carbon disk brakes rather than traditional steel-type brakes. They offer a considerable weight advantage over steel and perform better under high heat conditions, absorbing and dissipating heat more efficiently.

Many carbon brakes stay on an aircraft for thousands of landings and many years before wearing out. However, because they remain in service for so long without required maintenance, they become susceptible to corrosion due to extended exposure to harsh elements and caustic chemicals from runway deicer.

Carbon brakes do not like feathered or light braking. Brake-wear will drastically increase during these conditions.

Carbon wear stacks are much more expensive than steel stacks, and most must be replaced as a complete assembly. Replacing a single damaged or worn disc is not authorized.

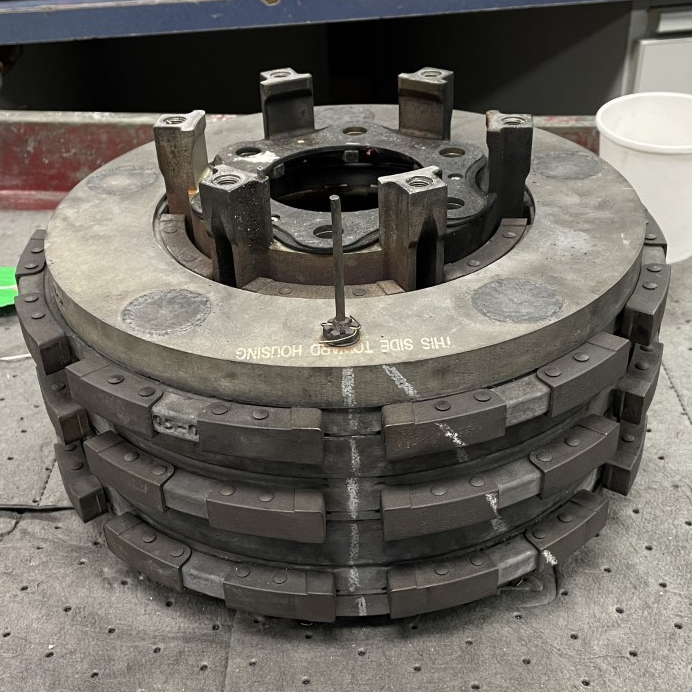

Although carbon is strong, it is very susceptible to impact damage that could lead to premature replacement of the stack (Photo 1). While some damage is acceptable, care should be taken to negate damage when removing and installing the wheel.

Because brake disks remain together for life in the stack, they will wear a pattern into the adjacent discs. Many Maintenance Manual instructions for removal and installation do not dictate the orientation of the plates except for the alignment of the wheel drive key slots.

Should any of the rotating discs be moved from their lifelong position, it could cause the brake to bind and drag, causing undo wear. It is recommended that the carbon discs be marked with chalk so the plates can be returned to the correct position before operation (Photo 2).

|

|

| Photo 1: Typical impact damage to carbon stack back plate. | Photo 2: Chalk markings on carbon stack to indicate alignment. |

February 2026

February 2026

February 2026

February 2026

February 2026