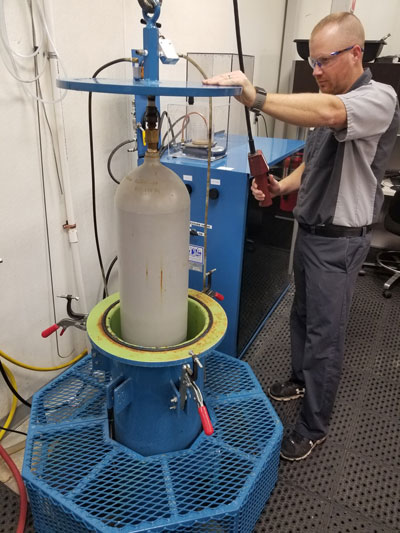

Hydrostatic testing is often required at certain intervals for aircraft oxygen cylinders, fire extinguishers and pneumatic bottles. The interval at which these are due and what is to be done is sometimes confusing.

Hydrostatic testing is often required at certain intervals for aircraft oxygen cylinders, fire extinguishers and pneumatic bottles. The interval at which these are due and what is to be done is sometimes confusing.

Some aircraft maintenance schedules require hydrostatic testing at five years while others at 10 years, and some reference all the way back to the DOT (Department Of Transportation) specification for the interval.

PLEASE NOTE: While these cylinders, extinguishers, and bottles are installed on the aircraft, the aircraft schedule takes precedence over the DOT requirements. Please reference FAA Order 8900.1, Volume 3, Chapter 57.

Valve Inspection

It’s not only important to know when these are due but also what is to be done. Many units have valves attached that also require maintenance to be performed during the hydrostatic test. This could be anything from a function test up to a complete overhaul. To comply with the scheduled task, all of the requirements must be met.

DOT Certified and FAA Certified

There are a lot of DOT-Certified hydrostatic testing facilities but not all of them are FAA-Certified 145 repair stations. Since units installed on an aircraft are both FAA-Certified as well as DOT certified, it is best to use a vendor that has both certifications, like Duncan Aviation. Be sure to communicate with your chosen vendor what your expectations are and what maintenance is required.

Paperwork

When you receive your units back, double check the paperwork that is returned to ensure all tasks were completed. At a minimum you should receive an FAA 8130-3 for the assembly and a DOT Certificate of Conformance for the hydrostatic test. The hydrostatic test is covered by 49 CFR and not 14 CFR; therefore, it should not be documented on FAA 8130-3. In addition, you may have an 8130-3 for the valves or other associated equipment requiring maintenance.

If the aircraft scheduled maintenance does not list an interval for the hydrostatic test, the 49 CFR 180.209 details the DOT required interval.

|

Specification under which |

Minimum test pressure |

Requalification period |

|

DOT 3 |

3000 psig |

5 |

|

DOT 3A, 3AA |

5/3 times service pressure, except noncorrosive service (see §180.209(g)) |

5, 10, or 12 (see §180.209(b), (e), (f), (h), and (j). |

|

DOT 3AL |

5/3 times service pressure |

5, 10 or 12 (see §180.209(e), (j) and §180.209(m)3). |

|

DOT 3AX, 3AAX |

5/3 times service pressure |

5, 10 (see §180.209(e). |

|

3B, 3BN |

2 times service pressure (see §180.209(g)) |

5 or 10 (see §180.209(e), (f)). |

|

3E |

Test not required. |

|

|

3HT |

5/3 times service pressure |

3 (see §§180.209(k) and 180.213(c)). |

|

3T |

5/3 times service pressure |

5 |

|

4AA480 |

2 times service pressure (see §180.209(g)) |

5 or 10 (see §180.209(e) or (h)). |

|

4B, 4BA, 4BW, 4B-240ET |

2 times service pressure, except non-corrosive service (see §180.209(g)) |

5, 10, or 12 (see §180.209(e), (f), and (j)). |

|

4D, 4DA, 4DS |

2 times service |

5 |

|

DOT 4E |

2 times service pressure, except non-corrosive (see §180.209(g)) |

5 or 10 (see §180.209(e)). |

|

4L |

Test not required. |

|

|

8, 8AL |

|

10 or 20 (see §180.209(i)). |

|

Exemption or special permit cylinder |

See current exemption or special permit |

See current exemption or special permit. |

|

Foreign cylinder (see §173.301(j) of this subchapter for restrictions on use) |

As marked on cylinder, but not less than 5/3 of any service or working pressure marking |

5 (see §§180.209(l) and 180.213(d)(2)). |

February 2026

February 2026

February 2026

February 2026

February 2026