All OEMs allow for time limits, or tolerances, on inspections to be extended for maintenance scheduling purposes. This is helpful when planning for maintenance events around a busy flight calendar.

The specifics to how many extra flight hours or calendar months can be found in the Chapter 5 requirements of your AMM.

But when calculating the due date of the next inspection, does your time reset to zero or do you take into account the extra tolerance?

According to the FAA, inspection tolerances are not cumulative. All inspection due times must be calculated from the due time of the previous inspection completed, NOT from the actual point of completion.

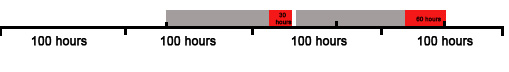

If an inspection is due at 100 hours and a tolerance of 30 hours is allowed, an operator must have this inspection completed no later than 130 hours of operation. However the next 100 hour inspection will be due 70 hours later, subtracting the 30 hours tolerance already used.

At any time the FAA can require you to recalculate your inspection and hours. If you haven’t taken the tolerance into consideration, you may have over flown your inspections.

Due points and tolerances are not OEM specific and very depending on the make/model of your aircraft. For information relevant to your aircraft, consult your Duncan Aviation Tech Rep.

February 2026

February 2026

February 2026

February 2026

February 2026