The aircraft came in for a 96-month airframe inspection, avionics upgrades that included a CMS (Cabin Management System), LED lighting, Gogo Avance L5 connectivity, complete interior and paint.

Designed with pictures the owner provided, Duncan Aviation’s Interior Completions experts collaborated on the interior of this 2010 Gulfstream GV-SP to give him exactly what he requested. The completely refurbished interior is highlighted by a custom stand-alone credenza with a rounded waterfall edge and automated flip-up monitor designed by the Cabinet Shop and Engineering & Certifications Services. The automated flip-up monitor was a first for Duncan Aviation, and can be controlled by the galley master touch screen or from the passengers’ controls at the conference table location.

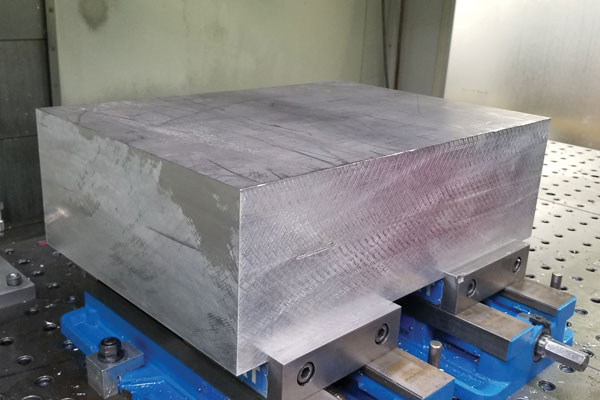

The aircraft is full of custom items created by the Interior Completions team to match the design requested by the customer, including PSUs (Passenger Service Units), cabin side ledges, and lower side walls. A special router bit was designed and fabricated in order to make the edge of the credenza end caps and custom side ledges. Custom cup holders were also fabricated to follow the contour of the custom side ledges. The customer had located a sink he liked, so the Fabrication Shop machined a 150-pound block of aluminum (pictured above) into a one-of-a-kind, 6-pound custom sink in which 95% of the cutoff was recycled and reused. New stone countertops were also installed and had to be designed around how the sink was going to be installed. Our teams stripped the old cabinets of the existing veneer and applied new veneer per the designer and customer request. Several of the seat bases were modified to be able to be put back into their properly stowed positions, and custom arm rests were created. We installed a patterned carpet, with a custom color combo.

In addition, the outdated lights were replaced with longer-lasting, energy-efficient LED lights to match the color tones of the interior. Custom LED accent lights around the card table frames and credenza were designed by the Cabinet Shop and Engineering and Certification Services. This proved to be challenging due to the fact that standard aviation LED lighting is not designed to match the required contour needed to meet the design and look.

Watch the transformation in under 2 minutes: