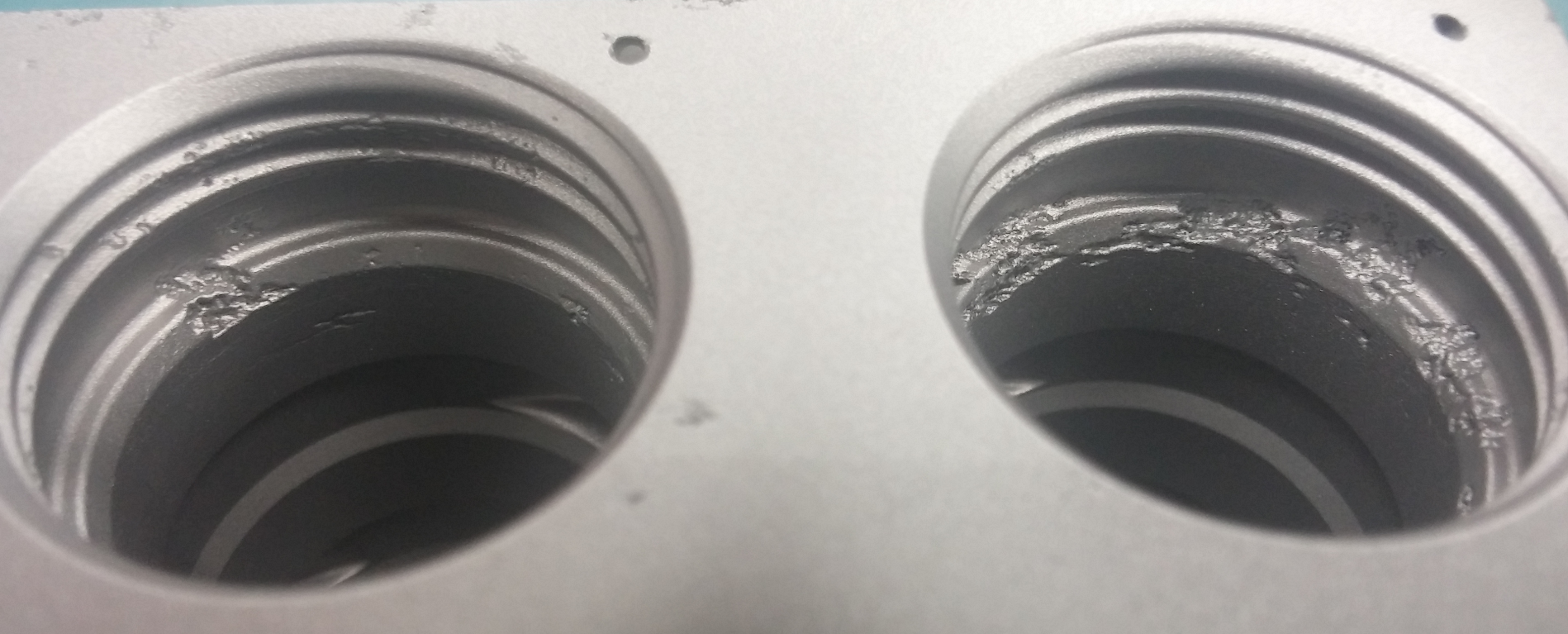

Duncan Aviation’s Accessories shop has worked on a number of the Anti-Skid Valve units (PN 39-853) found on the Bombardier Challenger 300 and Challenger 350 aircraft*. Because these units sit in the wheel well, they are exposed to high amounts of moisture, contaminants, and vibration, all elements that promote the growth of corrosion. Therefore, during a typical repair or overhaul event of these units, it does not come as a surprise when we find the unit plugs to be highly corroded and in need of repair. If the corrosion on these plugs is left unattended, it could begin to eat away at the adjacent bore material and potentially lead to a number of squawks, including leaking fluid, servo valves out of adjustment, or brakes locking up.

Examples of corrosion on Anti-Skid Valve plugs and bore holes.

Replacement anti-skid valve plugs are in short supply and very difficult to locate, potentially causing a delay in the repair with longer turntimes. However, we have developed two repair solutions that will eliminate the wait and be more cost-effective.

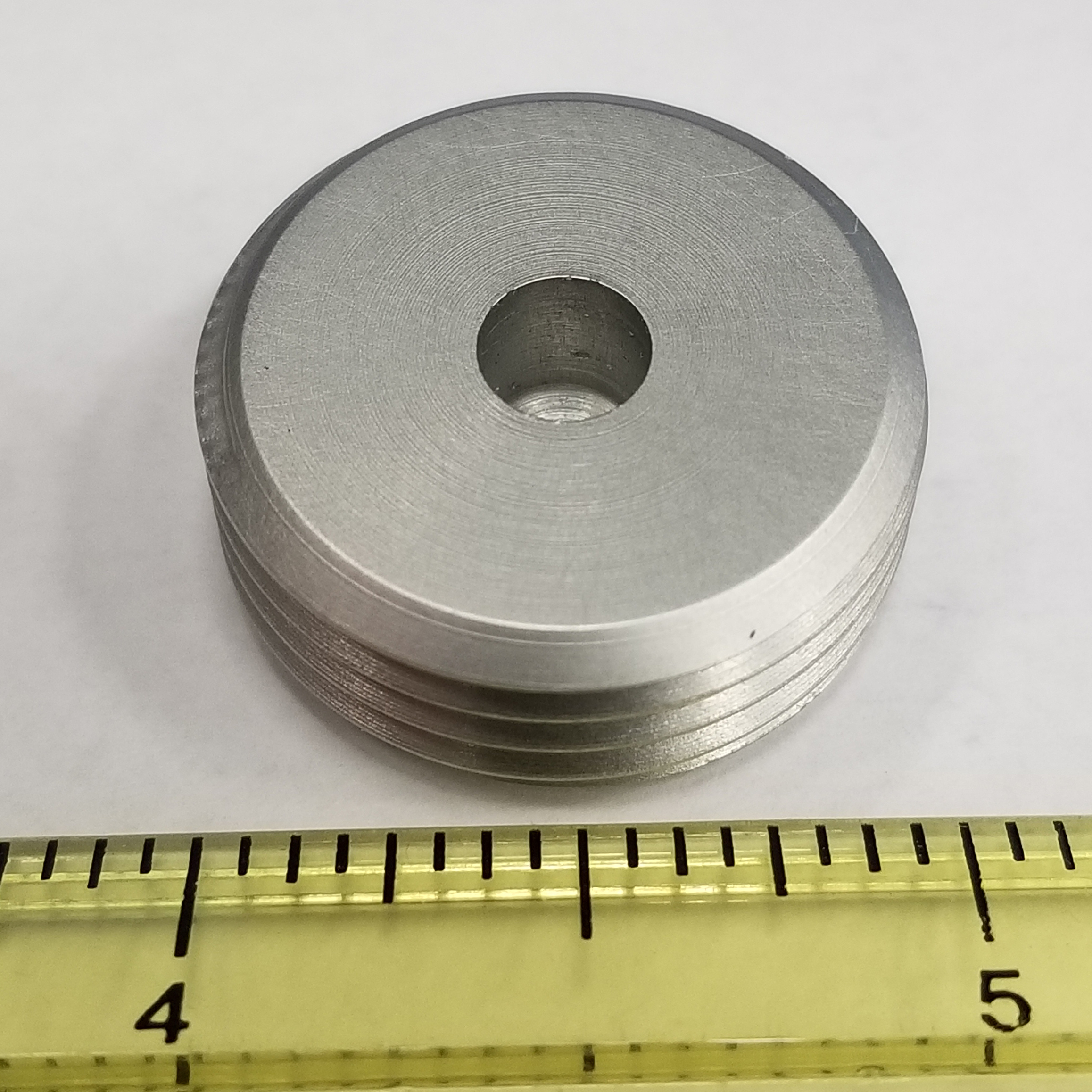

The first repair procedure is a new fabricated** anti-skid plug made of aluminum alloy and sealed with RTV106 to inhibit the onset of future corrosion. This plug was developed by the Duncan Aviation PMA team and is in stock and readily available for units sent to us for repair. We cannot sell these as piece parts.

The first repair procedure is a new fabricated** anti-skid plug made of aluminum alloy and sealed with RTV106 to inhibit the onset of future corrosion. This plug was developed by the Duncan Aviation PMA team and is in stock and readily available for units sent to us for repair. We cannot sell these as piece parts.

The second Duncan Aviation repair procedure cleans up the corrosion in the bores that surround the plugs by removing the corroded material and building the bores back to original dimensions.

For more information about this repair procedure, feel free to contact me anytime. To schedule a repair or overhaul of your anti-skid valve units, contact a Duncan Aviation Customer Account Rep.

*Bombardier, Challenger 300 and Challenger 350 are trademarks of Bombardier Inc. or its subsidiaries.

**Authority To Fabricate Parts

Under the authority of the FAA (Federal Aviation Association) Duncan Aviation is authorized to fabricate parts under the authority of 14CFR, Part 21, Section 21.9 (commonly called "repair station produced parts"). Duncan Aviation does this under our procedure GPP-0105 found in our RSGOM, and is done so by the FQCS (Fabrication Quality Control System).

Honeywell Ensemble & EDG-100: Enhanced HTF7000 Engine Data Management

Peace of Mind Beyond OEM Warranty: Why CASP is the Smart Choice for Avionics Protection

Five Consequences of Ignoring Landing Gear Trunnion Corrosion

Aircraft Engine Low Utilization Inspections (LUI): When They're Really Due

2024 Highlights: Global Reach, Aircraft Sales Insights, and Market Expertise