At the beginning of 2021, Duncan Aviation’s Component Services in Lincoln, Nebraska, took on a significant challenge and assumed all responsibilities for the repair, sale, and exchange services for a specific group of Honeywell Aerospace avionics legacy platforms flown on a wide range of business jets, turboprops, rotor-wing, and regional/commercial make/model aircraft. These include Flight Controls, Electronic Flight Control Instruments, Air Data, and Attitude Heading Reference Units on legacy platforms.

“We are no longer just the broker,” says Andy Theis, Duncan Aviation Rotable Manager. “If customers have a need to purchase, exchange, or repair these units, they now come to us. We have full control of the inventory, repair services, and customer service.”

Component Services doesn’t take this new responsibility lightly.

“In a short amount of time, we were given a whole lot more accountability,” says Eric Bettger, Duncan Aviation Customer Sales & Service Representative. “Almost immediately, we started hearing from our new customers, as well as an increase in business from existing customers. Our challenge has been to make sure our customers, both existing and new, know they are our priority.”

For many, this is their first experience with Duncan Aviation. These new customers are quickly learning that delivering customer service and communication is a high priority.

“We answer the phone,” says Jack Smith, Duncan Aviation Parts & Rotables Sales Team Leader. “It doesn’t matter what time of day or night. We offer real-time, in-person customer support 24/7/365.”

Jack adds that when customers call, they want honest and up-front answers. “There is no sense in beating around the bush. If we don’t have a unit available, I tell them. Then I walk them through the options and processes to find it. I always err on the side of over-communication.”

When it comes to the status of a unit at Duncan Aviation for repair, Team Leader Eric Bettger, agrees. “Customers want to know what’s going on and when they will get their units back. It’s important to tell it like it is. It’s a fair question that deserves a straight answer.”

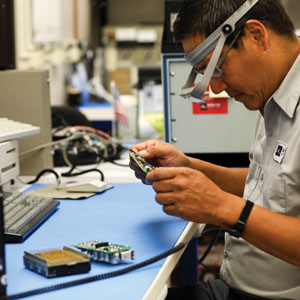

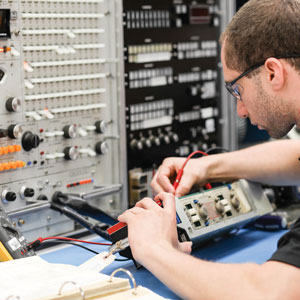

The customer service teams are right next to the service shop where the units are being worked. If there is any question about the status of a unit in the system, Eric and other customer service team members get up and walk directly to the bench and speak to the technician working on the unit. “We have direct access to the technicians. They are more than helpful in giving us the latest update. With this information, the customer is called back. We will not leave a customer hanging.”

Everyone on the customer service team has been through many training sessions to become familiar with the units and has full access to the entire workorder system. With one phone call, customers learn the unit’s current status, get an estimate on when they’ll get it back, or file an MSP claim. Duncan Aviation will fully facilitate all claims from beginning to end for all component customers on the Honeywell MSP program.

“We are the go-to resource for these units,” says Crystal Osmera, Component Customer Account Supervisor. “Whether calling to exchange, purchase, or send a unit in for repair, we have the right people in place to provide an elevated level of customer service.”

Duncan Aviation customers who have aircraft in the hangars or at any of the many Duncan Aviation Satellites are also seeing the benefit of having immediate access to this new inventory. Technicians can see and order the available units through the online inventory system. They will be delivered the same day if they are onsite or the next day if at the Satellites.

A dedicated parts warehouse was constructed for the estimated 2,000 new Honeywell units. An army of Duncan Aviation team members worked many hours to organize and sort these units onto shelves.

Customer reaction to this transition has been mixed. Those who have worked with us before are excited to have access to these units through Duncan Aviation. New customers are learning who we are and experiencing our 24/7/365 support for the first time. They like what we’re doing.

Duncan Aviation has been supporting these new units for the better part of a year. But there is still much to learn.

“We welcome customer feedback to learn and improve,” says Keith Schell, Component Repair and Parts & Rotables Sales Manager. “We continue to partner and engage with customers in order to ensure they are satisfied with our services and products.”

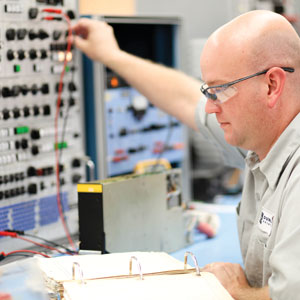

The influx of new repair capabilities has directly impacted many repair service teams, including Autopilot, DME, HSI, Gyros, and hydraulics.

“To say we have been busy is an understatement,” says Steve Krings, Avionics & Instruments Team Leader. “We have hired new technicians, but bringing them up to speed with the new equipment takes time. Bringing on a new product line and spooling up training at the same time needs serious synchronization. But we’re getting there.”

One point Steve emphasizes is his teams will not sacrifice quality for speed. “We are up front and honest with the customer about our current capacities. Sometimes units take longer than anticipated. In general, customers are willing to wait. They understand what we’re up against and that we are committed to them. They trust in us because they know the quality we deliver.”

Ten Duncan Aviation Avionics & Instrument technicians received OEM factory training. They actively participated in the teardown and transfer of the test equipment to fully understand how to reassemble and calibrate correctly. More onsite training was performed at the Avionics Instruments Repair facility in Lincoln.

Our Avionics & Instruments service team is one of the largest in the industry. Its breadth of talent and experience gives flexibility when it comes to meeting customer demands. Many technicians are cross-trained to be able to work effectively on many work benches. “We move them around where the help is needed the most,” says Avionics & Instrument Team Leader Scott Samuelson. “Everyone is willing to step up and understands their responsibility to the customer.”

The growth from this Honeywell agreement has been felt across the company. Here are some of the areas touched by this work:

Many of the new Honeywell units are new to Duncan Aviation. Rotable Manager Andy says it has been a challenge to learn what the most in-demand units are and keep inventory levels up.

His mission is to instill customer confidence that Duncan Aviation isn’t going anywhere and is in full support of the units.

“These legacy units are good, solid equipment. They have supported many aircraft for a long time. When they are properly maintained, they have a lot of life left,” he says.

Duncan Aviation is growing. Component service and repair teams are growing. Inventory is growing. Part sales customer service is growing.

We’re not going anywhere.