Bombardier Learjet Horizontal Stabilizer Actuator

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

The Duncan Intelligence is a free, technical newsletter for business aircraft owners and operators. Written in-house by Duncan Aviation's technical representatives, each edition includes technical tips and advice on topics and trends in business aviation. It is a free, monthly e-mail subscription for aviation enthusiasts around the world.

Subscribe now to receive the Duncan Intelligence in your inbox.

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

Sulfation of the plates and damaged terminal studs are common warranty claims that can be prevented or lessened by following simple operational and maintenance procedures.

Troubleshooting an autopilot altitude hold INOP squawk involves a complicated decision tree that includes several steps and scenarios. Here are three questions to get started.

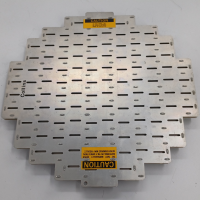

Maintaining the integrity of your weather radar antenna is vital for accurate hazard detection and flight safety. From inspecting physical warpage to ensuring correct system strapping, precise maintenance prevents the false returns and signal smearing that can compromise a pilot’s view of the sky.

When valuing an aircraft, you either have complete, consecutive, and original logs or you do not. During a pre-purchase evaluation, the logbook plays a major role, and vague or incomplete statements can be troublesome and delay closing.

This is not a mandatory Service Bulletin, but it is highly recommended that all Falcon 2000EX operators take it seriously.

The generator control panel controls the voltage for generators that charge batteries, start motors and control the ground power unit. When working properly, these generators share the electrical load.

Some Hawker and Beechcraft operators may not be aware there is a wealth of information in the Technical Publications area on the Beechcraft website regarding changes not yet been incorporated into the affected manuals.

There is a new Evolved Maintenance Program (EMP) for the Learjet 40 and Learjet 45 aircraft. We recommend you spend the time to become familiar with all the necessary documents.

If the static port on your Falcon 50B/EX has an added shim, extra caution is needed during removal as not to cause damage.

Because of our long history and experience with the Learjet aircraft, we know the most commonly exchanged parts and keep an inventory available to meet customer needs.

For the Pratt & Whitney 500 engine models, there are a number of Service Bulletins that have become hot items. These can be accomplished at access for cause but they will be addressed at either a Hot Section Inspection or overhaul, whichever occurs first.

When the landing gear actuators on the King Air 90 and 200 arrive at Duncan Aviation for overhaul, the first thing we inspect is the actuator screw and nut end play assembly.

During the next walk around of your Falcon 2000, pay close attention to the small door roller bracket that is mounted on the aft lower corner of your opened baggage door.

It is a very simple process to troubleshoot altitude and airspeed indicators if you have a spare indicator available.